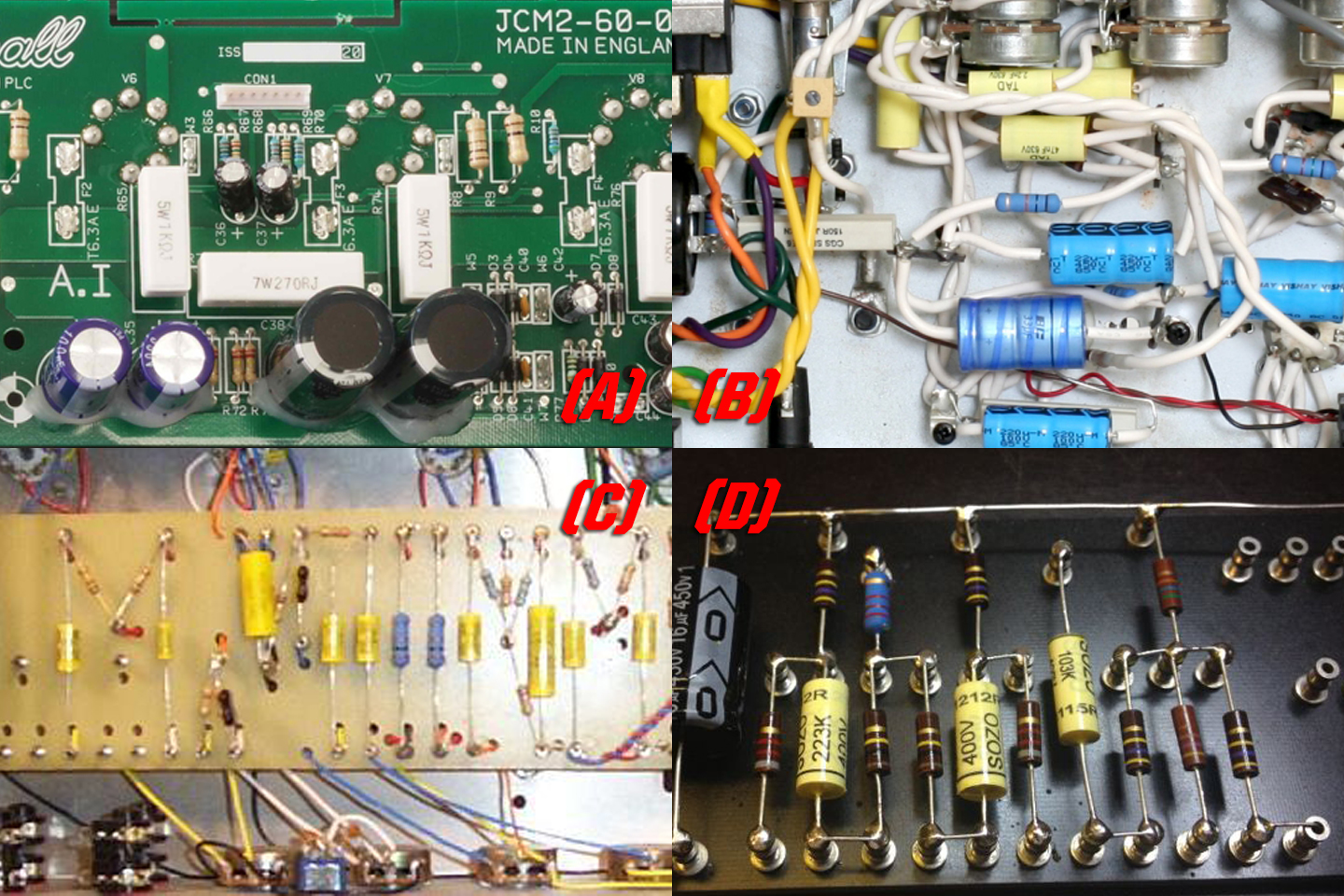

LEFT: Showing bias testing using a proper bias probe. RIGHT: Good bias tester/probe.

What is tube biasing? OK, so all tubes, to hit their optimal tone and operation, need a certain amount of current. However, remember that tubes are hugely outdated technology only made in a few places in the world now and so they are HIGHLY inconsistent. Consequently, from tube to tube, each individual tube may require more or less voltage to get to its optimal operation point.

Consider a Corvette engine in a Corvette. It needs a certain amount of gas to get that Vette up to 70mph. Now, put that same engine in a GMC 1/2 ton pickup. Same engine, but it's gonna take a lot more gas to get the truck up to 70mph. Now, let's change it up to better understand tubes. Let's say Chevy had those engines made in, um, not a country known for its manufacturing skill, so each time they get one in, engine 1 puts out 300hp, and engine 2 puts out 220hp, and engine 3 puts out 266hp, etc. Put them all in the same Vette and engine 1 requires less gas to get to 70mph than engine 2 and so on.

Now, assume that it takes 4 of those engines per car. Engine 1 is 300hp. Engine 2 is 220hp. Engine 3 is 266hp. And Engine 4 is 201hp. When I put a single gas supply to those engines (like the current in an amp), they'll all run differently and the car will be off balance. For those car nuts out there, consider this as a 4 barrel carb. What happens when they're not synched up?

When you set the "bias", what you're doing therefore is regulating the amount of DC current going to your tubes. As all tubes aren't created equal (even same manufacturer same tube type), this is the importance of getting "matched" sets. The more evenly your tubes are matched, the more evenly they'll run since I only get to send 1 DC current into the tubes. Basically, I need 4 of those Vette engines that perform about the same so when I supply a certain amount of gas (the DC current), the tubes all run at that optimal spot.

With tubes, that 70mph mark is magic. That's where the good stuff happens. The tube isn't straining because its starved for power and it's not over working due to too much current. In other words, it didn't under eat so it's still hungry, and it's not in a food coma due to a double burger and fries with a queso appetizer. That 70mph mark is measured with tubes by whether the tube is "drawing the right amount of current." That right amount is set by what tube it is, what the tube needs and what the plate current of the amp is. Biasing then makes sure that your particular tube is getting that right amount of current to hit that 70mph mark.

Due to the wide variance in tubes (even of they same type and brand), tubes therefore need to have the bias adjusted every time you change them. Yes, every time. But here's an often overlooked fact. Take a AAA battery. They work fine and then one day they just stop. Well, tubes aren't like that. They constantly degrade over the life of the tube. So here's a common phenomenon. Most guitar players one day just notice that their amp "doesn't sound the same." Guess what, sports fans, that's because your tubes passed their useful life probably a few years ago. Take a look at this:

Understanding that graph above, it's easy to understand why people make mistakes in deciding tube company x makes better tubes than tube company y. Generally, when a player switches from tube company x to tube company y, he's doing so at the bitter end of the the life of the tubes in the amp. So what he's really comparing is new tubes to old tubes.

So when do I bias? Well, there's generally speaking a few times. First, when you change power tubes, you ALWAYS need to check and adjust (or re-) bias. As well, as your tube life degrades, it doesn't hurt to have the bias checked and adjusted periodically to make sure your amp is running properly, maybe every 4-6 months depending on how much tube life you get (which is directly dependent on how much use your amp is getting, of course).

There is an exception to all of this - cathode biased amps. Cathode biasing is also called self-bias where the way the circuit is set up BASICALLY allows the tube to draw what current it needs. It allows the Vette engine (see above) to draw what it needs to run right and discard the rest. (for the tech savvy out there, yes, I know this is a radical over-simplification of this and somewhat technically inaccurate, but the technical accuracy of what is cathode biasing is totally unnecessary for the point of this blog entry). Cathode biasing, however, is typically seen only in much lower plate current (and lower wattage) amplifiers. Class AB amplifiers (most channel-switching, 50/100 watt, etc) require fixed/adjustable bias and do not work well off cathode bias to say the least.

Anyway, so what't the takeaway here? Unless your amp is cathode biased, yes, you need to have it biased when you change tubes and yes, you should periodically have that checked and adjusted as necessary.

PAY ATTENTION TO THIS: Most amplifier have lethal voltage inside. So you should NEVER set or adjust bias if you do not know how to do it. Please let a qualified tech do this for you. Further, always check with the manufacturer to get their recommended bias setting. They'll know what's best for their amp.

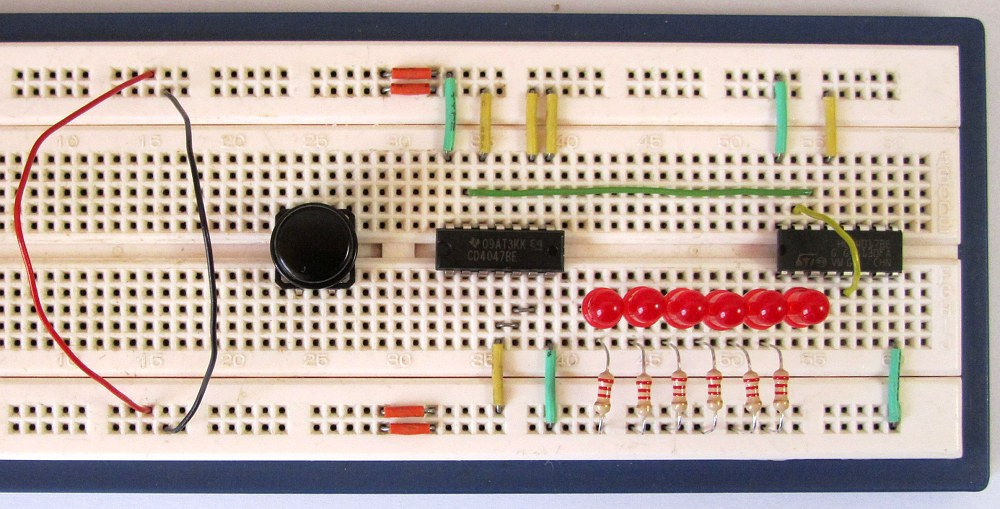

For those that do know how to do it, we recommend Fluke multimeters and Amp-Head Dual Bias Testers.